Watch Bands - Types of Watch Bands - the Watch Bands Wiki

We're sure that experienced watch geeks know-how just about any part of a wristwatch is named, but this is not the article for them. This guide is compiled to help newbies and watch geeks to be to better understand not just how the watch bands are made of but all the watch band parts as well as types of watch bands we should know. Learn how different watch band parts are named and what their function is down below.

Watch bands By Metal (Part A)

Stainless steel watch bands are widely liked among wristwatch lovers from several reasons. First, they go well with a range of outfit styles and can be a nice touch in classy, business and casual occasions. Second, they are long-lasting and low maintenance because they are well-resistant to corrosion and staining. Last, but not least, they are suitable for people prone to common allergies.

(A1) Watch Clasp spring bar secures the opposite end of a watch band to the clasp.

(A2) Watch Clasp spring bar hole serves for connecting the clasp to the watch band.

(A3) Micro holes have the function of flexible length adjustment.

(A4) Watch Clasp unfolds into 3 parts and can extend the length of watch band, to allow the watch band to fit larger wrists or big boned / knuckles.

Below you can see integrated & non-detachable spring bar details, two types, on the example of Seiko watch bands and MiLTAT watch bands.

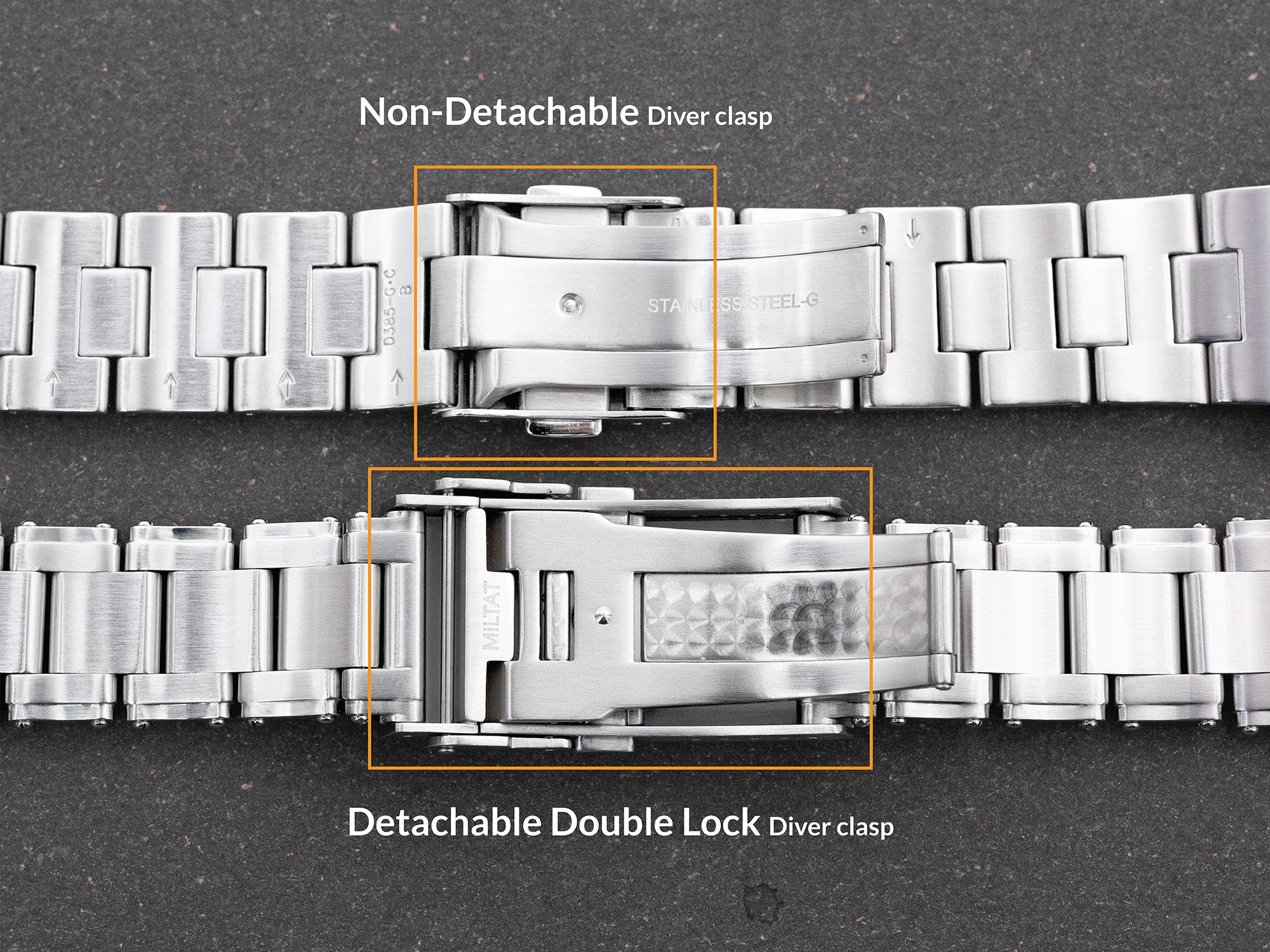

On the image below, you can see the difference of non-detachable watch diver clasp above (eg. Seiko watch bands ) and detachable double lock diver clasp below.

(A5) Removable link screws serve for adding or removing the links to adjust the length of the watch bracelet, but not all links are removable.

(A6) Link is one of many equal parts of the watch strap, that can extend or shorten it, but without compromising its design or functionality.

(A7) End piece / End link is the link that is closest to the case and attaches to it with an end link spring bar (A8).

(A8) End link spring bar holds the watch strap attached to the watch case.

(A9) End piece screw is the screw that holds the End link (A7) attached to its closest link (or so called second link), but not all stainless steel watch bands have detachable end link.

(A10) Tail short end spring bar serves as the connection between the ending tail of the watch band and the watch clasp (A4), this can be the same as (A1) or can be not.

(A11) Longer piece of the watch band is the one that needs to be attached to the 12 o’clock side, whose opposite end connects to the clasp's length adjusting end (A3).

(A12) Shorter piece of a watch band is the one that needs to be attached on the 6 o’clock side, whose opposite end connects to the clasp’s secure double lock side.

(A13) Materials used for stainless steel watch bands are usually stainless steel grades 304, 316 and 904. Due to its characteristics, grade 304 is on the cheaper end, as it is more sensitive than the two latter. Grade 316L is also known as the surgical steel and has a great quality-price ratio. Grade 904 is the most durable, hence the most expensive among these three, and quite hard to process and shape. Besides stainless steel, other materials commonly used for metal watch bands are titanium, 14K or 18K gold and sterling silver.

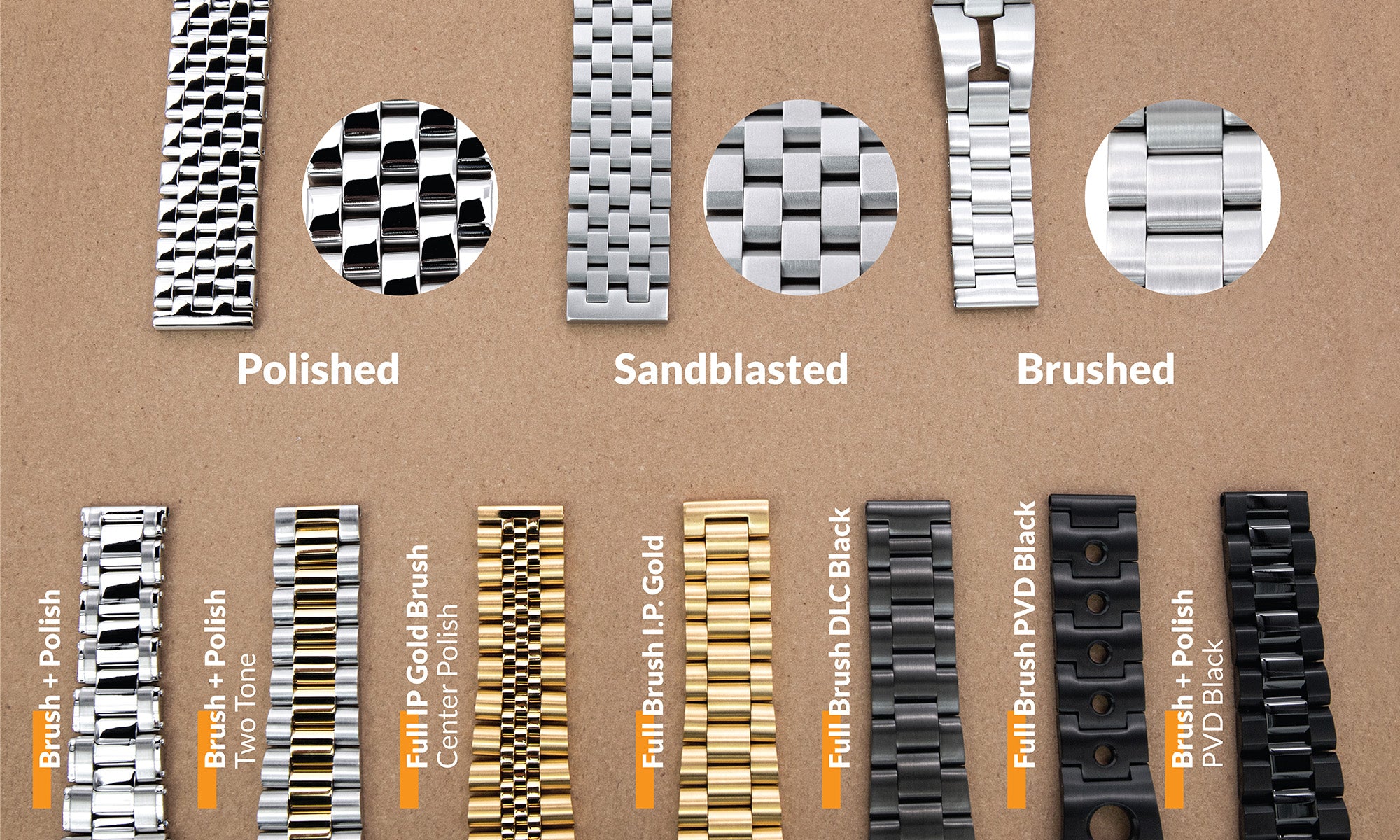

(A14) Metal finishes on metal watch bands can give your watch bracelet distinctive look. Most common stainless steel finishes in watch band industry are: Polished, Brushed, Brushed + Polished, PVD Black in Brushed, PVD Black with center Polish, Full Brushed I.P. gold, Full Polished I.P. Gold, Diamond Like Carbon Coating - DLC, Sandblasted, etc.

Watch Straps By Leather (Part B)

Similar to stainless steel watch band, leather watch straps never go out of fashion. The variety of styles and designs offers something for everyone, from vintage to robust looks. The process that turns animal skins into leather is called tanning, which can be mineral or vegetable, where the former is more robust, while the latter preserves much of its natural characteristics.

(B1) Case body is a watch case with watch mechanism inside.

(B2) Strap attaching portion is a piece of a watch strap that connects to the case.

(B3) Watch crown is the tool used for adjusting the time. Some watches offer a date window and seconds indicator, which are engaged by pulling the crown out.

(B4) Watch lug hole is the placeholder for a spring bar that keeps the watch strap securely fit to the case. Have in mind that there are different dimensions of watch lug holes so pay attention on the dimensions of your watch model lug holes when changing a watch band. Also note that there are opened and sealed watch lug holes, so if you have sealed lug holes, it isn't wise using watch bands with metal tube already in the lug (or metal watch bands without access points) because you may have trouble removing them.

(B5) Case back is the back of a watch that usually is the access to reach the watch movement, it may holds a logo and a model engraved in its cover.

(B6) Watch buckle or watch band buckle serves for keeping the opposite sides of the watch strap securely connected at your wrist. There are different types of buckles, such as folding buckle, deployment buckle / watch band clasp, butterfly deployment clasp, ladder lock buckle, slider buckle, tang buckle and so on.

(B7) Buckle tongue keeps the buckle closed and secures a watch around your wrist.

(B8) Watch buckle tongue width is an opening on a watch strap that needs to fit the buckle tongue. A thing to mind when choosing a buckle for your watch strap. The most common leather watch buckle tongue widths are 2mm, 3mm, 4mm and 6 mm.

(B9) Buckle Adjustment holes are the holes in the watch strap that serve the purpose of finely adjusting the length to comfortably fit your wrist.

(B10) Fixed loop / free loop or watch strap keeper, as their names say, free or fixed, depending on the watch strap and can come individually or in pairs. Fixed loop means that the loop is fixed to the band and can hold the excess portion of a band attached to the 12 o’clock side. Free Loop, on the other hand, isn't fixed to the strap and can move along its length.

(B11) Stitching can be done manually or with machine, hence it's called hand or machine stitching. It can have a functional or a decorative purpose. Wax stitching is usually used in hand stitching and has functional purpose, because waxing makes the regular threads firmer, more water resistant and less stretchy. For example, Hermès uses waxing for both stitching and leather finishes on their leather bags to protect them from humidity and make them last longer.

(B12) Watch strap profile determines the shape of your watch strap. It includes the fit on the watch lug, leather watch strap edge finish and the form of its tail / tip. You can see different profiles on the image below.

(B13) Lining of leather watch strap is the inner side / back layer of the strap that lies on your wrist. The most common material used for the lining in leather straps is natural leather, but it can also be some other material, such as rubber.

Watch Bands General Terms (Part C)

(C1) Watch lug width determines the width of the watch straps that fit your watch. Common lug widths nowadays are: 18mm, 20mm, 22mm & 24mm. Odd, rarer lug widths like 19mm or 21mm are usually fit with vintage watches.

(C2) Shape of watch bands is usually the model or outline of your watch strap. Common shapes are straight through and tapered shape, or sometimes referred as style, seen below.

(C3) Allergic properties of a watch strap are usually determined by the material a watch strap is made of. Naturally, if you're prone to allergies or have any material sensitivities you may want to carefully choose your watch straps. Stainless steel watch bands are a great choice that will have most of the people safe, but if your skin is delicate, titanium may be a better choice for you. When it comes to leather watch bands, vegetable tanned leather is more skin tolerable than the mineral tanned leather. There are also leather watch straps with anti-allergic, sweat resistant back lining.

Watch Straps by Nylon (Part D)

The so-called one-piece long watch straps have a big family "One-piece Nylon watch straps", which makes them highly adjustable to any wrist size. They are usually made of nylon or textile and hence suitable for summer wear. On the image below you can see some of the common types of watch bands made from this family:

(D1) RAF strap with one big keeper(D2) Perlon watch strap is plaited. Both (D1) & (D2) one piece long straps' detachable ladder lock buckle can simply be inserted anywhere through the strap rather than through pre-cut holes, with loose (or 'floating') keeper on them.

(D3) One-piece Nylon watch strap / James Bond strap with slim and lightweight Sewn-in buckle and keepers

(D4) One-piece Rings strap with thicker and heavier Sewn-in buckle and keepers

(D5) One piece watch bands are the bracelets whose length adjustment is limited to the buckle micro holes. They usually have the higher longevity than the former and may be more practical (image below).

Mesh Watch Bands (Part E)

Mesh watch bands are watch bracelets made from metal wires (usually stainless steel) worked into characteristic mesh look that can give either robust or sophisticated look to watches, depending on their style. On the image below you can see some of the common types of mesh watch straps:

(E1) Milanese Mesh with slide lock length adjustment details

(E2) SHARK Mesh, a more robust watch strap, firstly seem on Omega Seamaster Plofproof 600 m in 1970s and advertised as prone to shark bites, which gave it its name.

Perforated watch straps (Part F)

Perforated watch straps are easy on the skin in terms of ventilation and sweat, which is especially helpful in extreme situations. Therefore, perforated watch straps are usually called Racing or Rally watch straps because they are popular among racers. On the image below you can see racer watch straps with porous holes made from leather and stainless steel.

BUND Watch Bands (Part G)

BUND watch straps have the leather part covering the back of the watch case. They originate from the 1970s, when German air force placed their pilot watches on the thick leather pads, to protect their wrists from harsh temperatures affecting the watch case. They quickly became popular among wider public. Famous people that wore BUND watch straps were Elvis and Miles Davis.

Quick Release watch bands (Part H)

Quick release watch bands brought a major progress in the way of replacing watch straps. They are detached from the watch by simply pulling the knob on their spring bar, which in turn pulls one spring end out of the hole on the watch case and they are attached by reverse action. The whole process of changing a watch strap takes seconds, instead of minutes.

(H1) Quick Release leather watch bands, seen below

(H2) Quick Release FKM rubber watch bands, seen below or video HERE

(H3) Quick Release Stainless Steel watch bands, seen below

Rivet Lug Watch Bands (Part I)

Rivet lug watch bands or, simply, rivet bracelets or riveted watch straps, have the visible rivets on their outer edges that hold together the folded parts, why they are also called folded link bands. This style of watch bands is popular among aviators, hence they are nicknamed pilot, aviator, or flieger watch straps.

Watch Bands Tools (Part J)

Now when you know everything about watch straps, here's your quick guide on the use of professional tools for watch strap replacement.

(J1) Soft Mat will protect your watch and all watch band parts from damage and getting lost around. Plus, it will serve as a comfortable pad, therefore helping you avoid unnecessary movements while you work. The photo below showcases a semi-soft, non-slippery mat found in out toolkit. It will keep all the small screws in one place, plus help you protect both your watch and your watchband from getting damaged and scratched by accidentally hitting hard surfaces.

(J2) Screwdriver is one of the most important tools for bracelet replacement. It mainly serves for loosening or tightening screws on your watch's bracelet. It comes with several different tips which cover all sizes of typical MiLTAT stainless steel watchbands. The most common tip size we use here at Strapcode is 1.6 mm, but in some cases, we resort to a 1.4 mm or 1.8 mm tips (for thinner or heavier bracelets, respectively).

Precision Screwdriver Cut-Out type for Watch Band adjustment NT-SD-012MA

(J3) Tweezers - Your watch and your bracelets often contain such small hands that your fingers cannot help much, regardless of their size. Especially when it comes to pins, but also of good use with screws and other tiny parts, tweezers are your number 1 helper. It will help you reach and pick any small part without effort, and put it in a safe place to avoid losing it in the process.

(J4) Spring bar tool - Changing your watch band is quite easy, regardless of types of watch bands, but regardless of their kind, this job cannot go without a good spring bar tool, or, as some call it - multi tool. The Spring bar tool has two working ends: a fork end on one and a pin end at another end. Fork end serves for adjustments with spring bar flange, while pin end can be used for removing spring bars through the holes on your watch case and micro adjustments of the pins on watch buckles.

Spring Bar Tool, Watch Band Tool for changing watch straps NT-SBT-014JP

(J5) Magnifier - To those who are in need of glasses and to those who aren't, having a magnifier when looking at the tiny drill holes on their watch bands is a lifesaver. Another purpose to use a magnifier is to be able to help examine if the spring bar is fitting the lug holes properly.

(J6) Spring bar bending pliers -The main purpose of spring bar bending pliers is just one of the names for watch pin curving tool or spring bar bender. This is a useful tool for cases when your spring bar needs adjustments in order to fit the watch case. Don't take it as a helping tool if you miss the size completely though (only buying the proper one can help in that case). Spring Bar Bending Pliers can help adjust the curve and shape of the bracelet spring bar to fit your watch flawlessly without damaging it. The jaws of the bending pliers are made of high-impact nylon and grooved to hold the spring bar in place while bending. The body of the pliers is made from stainless steel and has a handy grooves on its hands, for a better grip.

Watch Band Pin Bender / Spring Bar Curving Bending Plier, NT-SBP-011LD

(J7) Digital Caliper - Digital calipers are measuring instruments commonly used for inspection in manufacturing to provide the precise measurements of an object. One jaw is fixed to the end of the scale, while the other jaw slides along it with precision to take measurements. The reading is electronically generated and displayed on a digital, high-resolution screen as a single value. They can help you precisely take any measures you may need to pick and set the new bracelets on your watches.

(J8) Watch band pins and collars remover - This is another handy tool for pin type adjustment. It probably won't be needed for replacing the MiLTAT bracelets as we use screws instead of pins and collars, but it is super-useful when replacing Seiko stock bracelets for example, or any other bracelet that use pins instead of screws.

Watch bands link adjustment tool, pin and link removal tool, NT-BAT-003LS

(J9) Removable tape - The purpose of using tape here is actually not for its sole purpose to hold the bracelet together, as it may seem. Instead, its main purpose is to add a layer of protection from unnecessary contact with the tools to avoid scratches on the bracelet. A temporary mounting tape such as 3M™ Removable Reposition-able Tape 665 is most often recommended for this purpose.

(J10) Watch Band holding block - It can be very helpful to have a tool that can hold your watch band steadily without having another person hold it for you while trying to remove or a tighten a screw or a pin. When we first developed bracelet holding blocks, it was mainly for our tech team's use while adjusting the bracelets. Since we already had the mold made and thought customers would be interested to pick one up to use at home, we ended up putting it into production. The response was magnificent.

Watch Tools, Watch bands pins removing holding block NT-BAT-001LU

(J11) Watch Punch Pins - This is a watch band pin remover or link removal tool. Pushpins are ideal watch pin removal tools for metal watch bands with links held together by pins or push pins, such as Orient, Citizen, Seiko watch bands, etc. It is also helpful for uninstalling watch pins /spring bars from the type of watch lug with an exterior drilled hole / opened lughole.

Watch Band Pin Remover, Link Removal Tools NT-BAT-024-3SET

(J12) Watch hammer - A micro-hammer is also the purpose for removing friction pins while resizing your metal watch bands. For a smooth and secure application, two more tools should be used together to remove the watch band pins: Punch pin - watch band pin remover and watch band holding block. To use it, hold your metal watch band steady and in one place to avoid damage or hurting yourself (use a bracelet holding block). Then, adjust the pin punch over the desired pin and tap the punch lightly with the hammer until the pin pops through.

Watch Tools, Micro Hammer For Removing Watch Band Pins NT-WH-038

If you want to change your watchstrap on your own, take a peek at our short video guidance. And congratulations! Now you know everything about watch bands and how to replace them, like a professional!

Written by M.H. , images by Toni